Nobody wants to deal with heating, spoiling grain, so it’s important to monitor grain temperature and keep stored grain cool and dry by regular aeration or turning.

High moisture and warm temperatures in grain allow for rapid growth of insects, fungi and possible production of mycotoxins.

Why it matters: All the best field practices in the world won’t help if the grain spoils in the bin.

Read Also

White mould tops 2025 disease threats in Manitoba soybean fields

White mould was found in nearly two-thirds of surveyed Manitoba soybean fields during the 2025 growing season, but at a relatively low intensity in most cases.

Grain is a good insulator. When undisturbed, it holds temperature well.

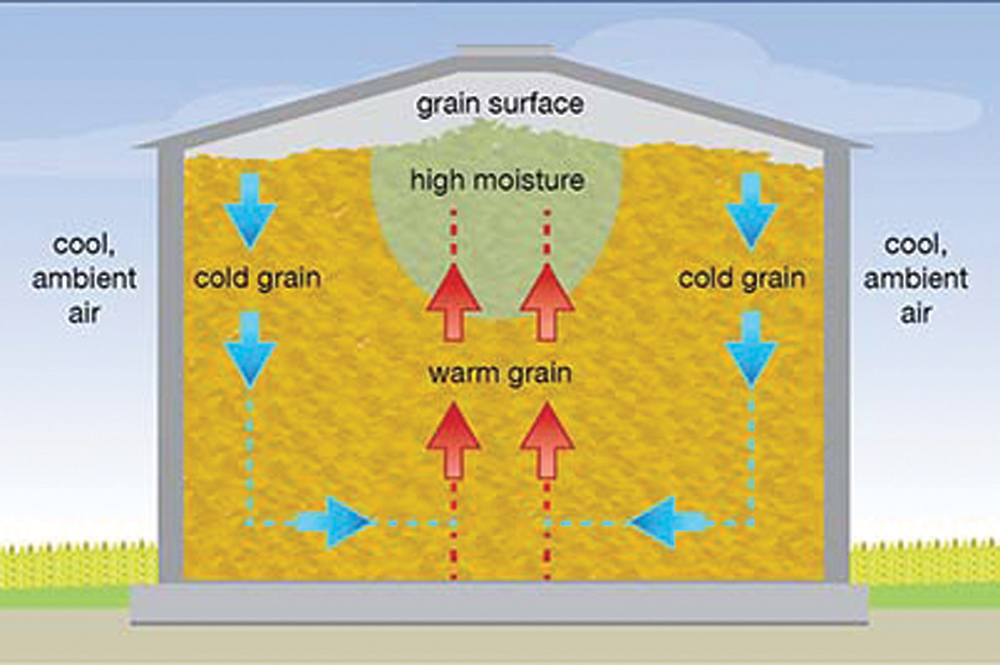

If warm grain is placed into storage and left undisturbed, convection currents develop and cause hot spots and condensation.

The greater the temperature differential (the difference between the temperature of the grain and the outside temperature), the stronger the convection currents. The stronger the convection, the greater the effect of heating and condensation on the grain.

This is particularly evident when stored grain is not levelled and the grain bulk forms a peak.

Grain at the surface and just below the surface has high moisture content. Warm grain is in the centre of the grain bulk. Cold air flows down from the surface of the grain, along the interior of the bin wall and surrounds the warm grain.

At the bottom of the grain bulk, cold air is drawn to the centre by an upward flow of warmer air. As the cold air is drawn to the centre of the grain, it warms and flows to the surface, where there is more moisture.

The warm air is cooled as it reaches the surface, condenses, and the cycle is repeated.

Determining moisture content

Grain with a moisture above grade requirements can create an environment conducive to insect and fungal development if it is not managed. Such unmanaged grain may heat, and subsequent convection currents can cause surface condensation.

To determine the moisture content of grain at storage, take samples from bins every three to four weeks after harvest if grain is not managed (i.e., no aeration or turning). Samples should be taken from several areas of the bulk and kept in sealed plastic containers prior to testing.

Monitoring temperature

Check the temperature of the bin every two weeks by using temperature-sensing cables that are permanently installed or by probing the grain with an electronic sensor.

If devices for measuring temperature are not available, assess the general temperature by inserting a metal rod into the grain at the top of the pile near the centre and at least one metre down into the grain. Leave the rod for approximately 30 minutes.

Once removed, test the rod for warmth at various points with the palm of the hand. Any section that feels warm is an indication of heating and grain spoilage.

How aeration systems work

Aeration systems preserve stored grain and keep it dry by reducing the temperature and reducing moisture migration. Appropriate aeration can prevent convection currents and condensation.

Physical characteristics of grain are important when considering aeration and drying. Grain class and storage configuration affect the static pressure and aeration fan requirements. In general, as static pressure increases (for example with increased height of the storage or change in the class of commodity in storage), the amount of time required to properly aerate also changes.

An aeration system provider can help determine aeration or drying times for the bin type or commodity.

How to use aeration systems

Stored grain should be aerated as soon as possible after harvest, particularly if aeration can reduce the bulk temperature below 18 C.

When the ambient temperature falls below that of the grain bulk, initially during the early evening, night and early morning, aeration can be used to reduce grain temperature.

If aerated when the ambient temperature is above 20 C and the temperature of the grain is above 30 C, the odours produced will be more attractive to insect pests. Sanitation involving cleaning and treating grain is critical to preventing problems.

As well as preventing insect infestations, aeration is effective in controlling them. Once the grain temperature is reduced below 18 C, (which prevents insect feeding and reproduction) a further temperature reduction can be used to kill them.

To gain the most from an aeration system’s capabilities, it’s important to understand the fan and motor proficiency and the static pressure of the commodity to be aerated. Charts are available, provided by the Prairie Agriculture Machinery Institute, to help determine the time required to aerate stored grain.

Other cooling methods

If an aeration system is not available, turning grain outside the bin is an alternative when the ambient air temperature falls below 15 C.

Turn the grain every two to four weeks until the grain temperature reaches 15 C. This procedure involves removing about one-third of the grain from the bin.

Grain chillers can be used to reduce the grain temperature when outside temperatures are above 20 C. Grain chillers reduce the temperature and moisture of air used to aerate the grain. Once grain is chilled, it remains cool for extended periods due to its natural insulating properties.

Grain mixing and stirring equipment is also a good way to assist in drying to reach uniform temperature and moisture content in stored grain.

Grain-stirring devices slowly move grain from the lower and central areas of the storage bin to the surface. This helps to mitigate the effects of moisture and temperature concentration caused by convection. These systems can be used in conjunction with aeration to reach and maintain a uniform grain temperature and moisture.