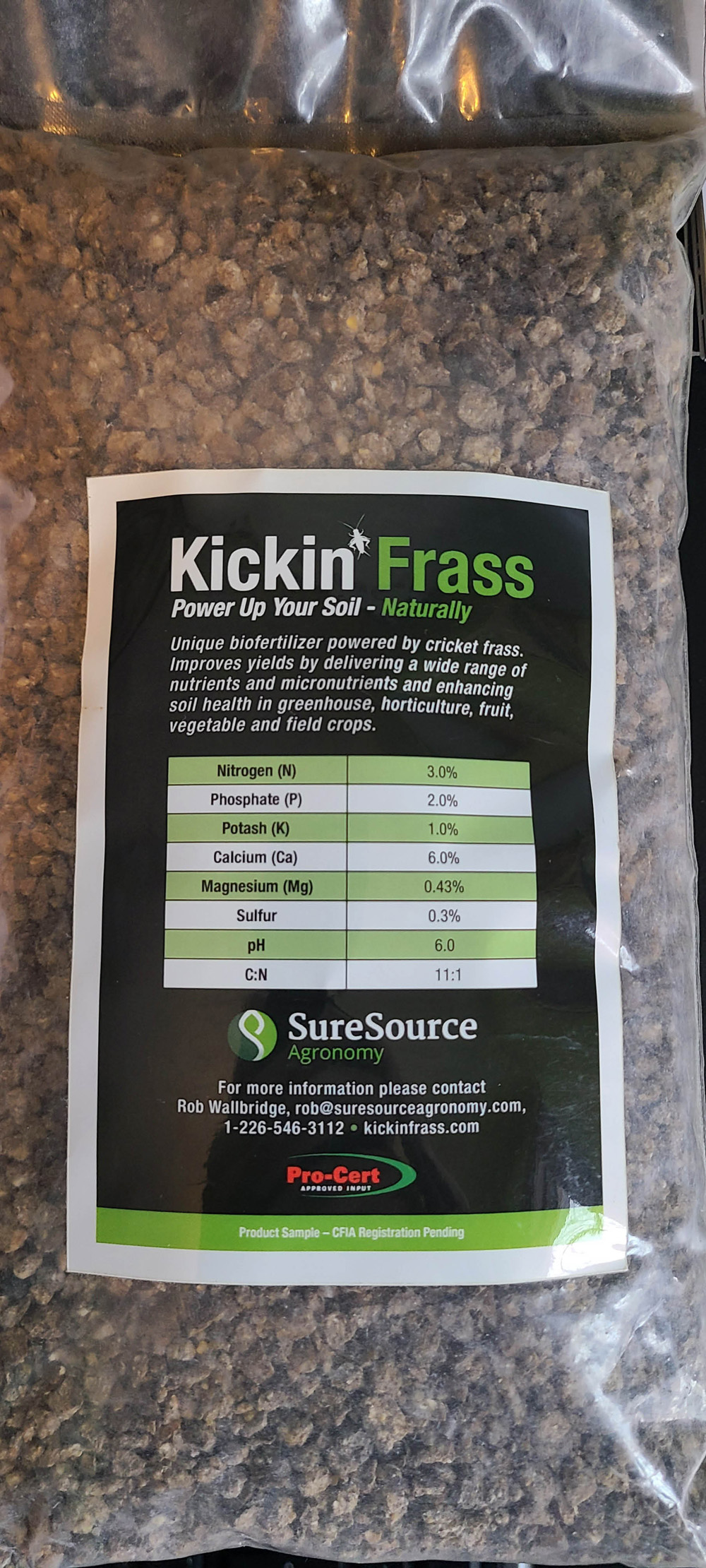

Glacier FarmMedia – Ontario-based firm SureSource Agronomy is rolling out a line of crop nutrient products derived from the excrement, exoskeletons and discarded feed materials of crickets.

The insects are raised in the firm’s Aspire insect farming facility in London, and their byproduct is called frass. The company announced Feb. 20 that it has received regulatory approval from the Canadian Food Inspection Agency for its pelleted product, Kickin’ Frass.

Why it matters: Cricket frass fertilizer is being marketed as a sustainable fertilizer option that does not sacrifice yield.

Read Also

VIDEO: Manitoba’s cabbage seedpod weevil explosion

Crop pest could pose a big problem for Manitoba canola growers in 2026 if last year’s population jump wasn’t a fluke.

In April 2023, the firm was among 10 companies granted $200,000 from the province of Ontario through the Fertilizer Accelerating Solutions and Technology Challenge, administered by Bioenterprise Canada.

Program applicants committed to use the money to “transition alternative fertilizer solutions from research and validation phases to successful commercialization and market entry.”

SureSource took its funds to the Vineland Research and Innovation Centre, and an agreement was signed to work toward commercialization of a pelleted fertilizer made from cricket frass. That work began immediately.

The new research collaboration led to several trials in 2023 – research highlighted in Vineland’s recently published 2023-24 Innovation Report.

“As an increasing number of insect farms come online in Canada, the question of how to deal with the resulting frass is one in need of a solution,” the report stated. “And it’s one that Vineland’s plant production experts are helping to answer.”

“The research has demonstrated benefits to incorporating frass in growing media for vegetables and ornamentals, as well as a fertilizer for greenhouse lettuce and cucumber production,” said Rob Wallbridge of SureSource Agronomy.

He suggested organic producers in particular could be attracted to the new products because “as the byproduct of a local, sustainable production facility, frass fits really well into the ‘circular economy’ concept of regenerative and sustainable food production.”

The report notes that “the in-house Vineland soil laboratory looked at the benefits of different frass formulations for use in field or greenhouse vegetable production; the plant pathology team investigated pathogens, bacterial and fungal components; and the biochemistry team looked at the frass’s specific metabolomic profile including chitin content.”

The report doesn’t reveal specific results from the trials but does state that “many of frass’s potential uses are similar to those of other manures, such as in beneficial soil amendments for both indoor and outdoor vegetable production. And similar to other animal livestock, frass from different insect species carries different characteristics which will influence end-use formulations and applications.”

Wallbridge shared some specific results.

“In greenhouse lettuce trials, frass out-yielded commercial organic fertilizers and resulted in higher chlorophyll concentrations,” he said. “Comparing frass to other top-dress fertilizers in greenhouse cucumbers, frass produced fruit a week earlier and yielded 19 per cent more over the production cycle.”

He also pointed to frass’s stimulation of biological activity and nutrient cycling.

“Trials (showed the product) can produce the same yields at much lower application rates than similar carbon-based fertilizers and soil amendments,” he said.

Prototypical formulations created by SureSource and Aspire were used in the 2023 trials. For 2024, those formulations have been adjusted and farmers can purchase the product as either raw frass straight from the Aspire facility, or as a processed crumble.

Wallbridge said that due to the CFIA’s early 2024 approval of the product as a registered fertilizer, the crumble “offer(s) the most flexibility and convenience for application.”

The SureSource/Aspire products are being promoted as the first launch of a commercial-scale cricket frass fertilizer in North America.

Wallbridge sees potential from early crop trial results and says the research collaborators are looking forward to learning more in 2024 and beyond.

“Crops that benefit from increased nutrient availability in early growth stages could take advantage of the quick nutrient release from frass,” he suggested. “Research has also shown higher than expected availability of nitrogen, phosphorus, potassium and zinc after frass applications.

“And the high organic matter content and increased microbial activity could be a great benefit in lighter-textured or degraded soils.”

SureSource said in a release that Kickin’ Frass will initially be available as a dry crumble. The product will be available in bulk, 1,000kg/2,204 lb. totes and 25kg/55 lb. bags. The company said it also has the capacity to do custom blending and packaging.