Unrepresentative grain samples are costing producers as much as $100 per acre and a small Saskatoon-based company aims to change that.

“If growers had better information as to what they have stored in their bins, there’s a lot more revenue they could be getting on some percentage of their crop,” says VeriGrain CEO and founder Ken Jackson. He recently brought that message to the Fields on Wheels conference.

Why it matters: Better sampling means better information with which to market a crop.

Read Also

Predictive weed mapping, coming to a farm field near you

Geco–Gowan deal taps AI tools, imagery, to forecast weed-patch-prone field zones, so Prairie farms can preemptively target herbicides

VeriGrain has been around for about 2.5 years and grew from a project that Jackson started 15 years ago. At the time, he was working on the latest wireless and web-based grain bin monitoring. But while that technology was humming along, on-farm grain sampling lagged in terms of technological innovation.

“It occurred to me that the only advance I had seen in my lifetime to that point was that we had graduated from a soup can on a cut-off, broken hockey stick to a plastic scoop,” says Jackson. “The roots of what has become VeriGrain started then.”

The plastic scoop wasn’t much of an upgrade and did nothing to improve the reliability of samples. Complicating matters further is the chaos of harvest time, when the samples must be taken.

The problem cascades from there. Without a truly representative sample, there was no way to get an accurate analysis. Without an accurate analysis, buyers aren’t confident in what they’re buying. And when buyers aren’t confident, they’ll try to squeeze farmers for a lower price.

“Buyers and growers have always been somewhat at odds for obvious reasons,” says Jackson. “In general, the buyers are trying to buy low and sell high, and the growers are trying to get as much as they can, so there’s sort of an inherent lack of trust there.”

In fairness to the buyers, Jackson says the samples they receive are rarely representative.

“Every grain buyer I’ve talked to says they do not trust what they’re getting for samples. From a grower’s perspective, knowing what’s in your bins can literally make you another 100 bucks an acre.”

He concedes that it won’t be $100 on every acre, but even if it’s 10 or 20 per cent of fields, it still represents tens of thousands of dollars on a typical farm.

Another issue that limits an optimal price for growers is not knowing whether the grain in storage is stable, “and of course that’s related to spoilage,” says Jackson. “And it doesn’t take a whole lot of warm, wet grain to turn into a pretty big loss.”

Traceability is the final issue that VeriGrain is addressing to bring grain sampling into the 21st century. It is increasingly seen as crucial for ensuring food safety, identifying potential contamination sources and protecting consumers from fraud or mislabeling.

“Traceability is becoming more and more of a requirement to get a premium price for your grain,” says Jackson.

The solution

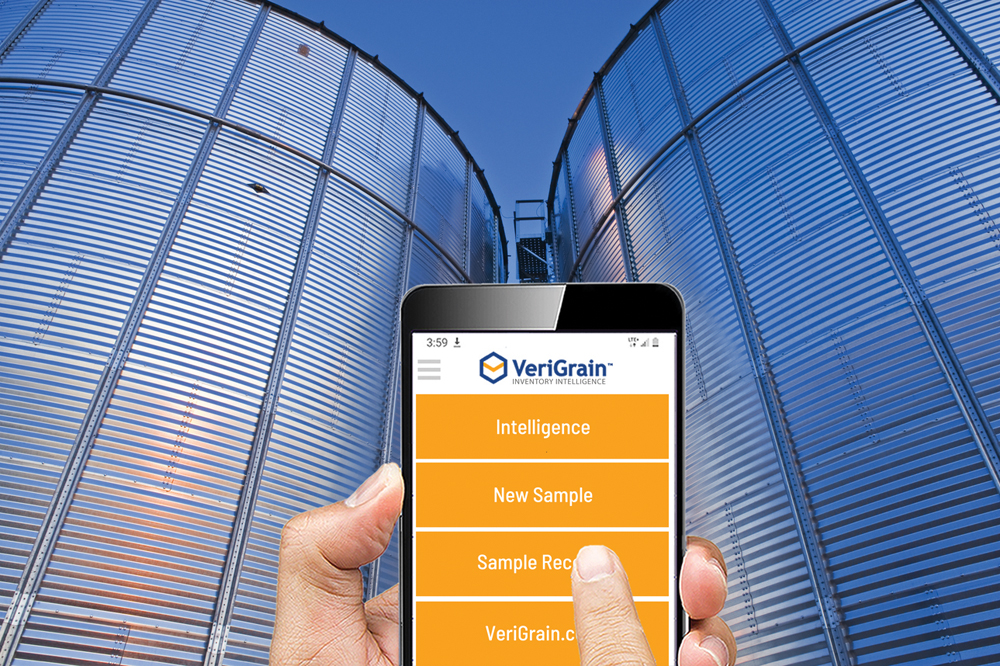

VeriGrain has a suite of solutions and they start with an app. Before the smart phone and its wide-scale adoption, the answer to some problems VeriGrain now addresses would not be possible. Now that everyone carries a powerful, pocket-sized computer, the solution is literally at hand.

“The introduction of the smart phone has totally changed the way we approach product development,” says Jackson.

The smart phone app takes care of sample management. At its most basic, it pings the farmer when it’s time to take a sample based on the flow rate of the handling system.

“We actually have some intellectual property around the calculation to determine the optimal sampling interval,” says Jackson.

The app also allows the farmer to connect with all major labs in Canada and interact with buyers (as long as the grower allows it), so the buyer can see what’s going into storage on the farm almost in real time.

And it’s still functional when there is no internet connectivity.

“We also had to learn the hard way that it has to function completely offline and have no ability to connect, because until Elon Musk has got the world surrounded with satellites, we’re going to have dead spots on the farm.”

VeriGrain provides the app free for the first year, but Jackson says users also have to commit to using VeriGrain’s proprietary, bar-coded sample pails and bags to make use of it.

The next part of the VeriGrain suite is a next-generation scoop on a stick.

“When you use a scoop on a stick, the lighter stuff tends to be concentrated on the edges, so as you take that scoop into the flow, it fills up quickly and isn’t representative,” Jackson says. “So we’ve created a tool that makes it easier to get a more representative cross-cut sample.”

VeriGrain also offers a higher-tech manual sampling tool it calls “the Smart Sampler.” It connects via Bluetooth to the farmer’s smart phone, and it has a strobe light that flashes when it’s time to take a sample.

However, all options require manual sampling and if a sample is missed because of the mad rush around harvest time, the data can’t be fudged. There is a three-star system, and too many missed samples will result in downgrading, and everything from that bin will lose a star.

However, VeriGrain’s next tier is what it calls the “Ultra-Sampler,” which is fully automated.

“We’ve got a couple of different approaches to how we can take samples, but it’s all microprocessor controlled and Bluetooth connected to the phone,” says Jackson. “So you just set it up for a sample, push the button, and walk away.”

The future

On the horizon for VeriGrain is the addition of a real-time moisture and temperature monitor, which it will add to the suite later this year. It also plans to test a real-time grain characteristic analysis this year.

“As the grain enters the bin, you can see the protein, starch, or any other relevant characteristics that you want to know,” he says.

“It’s not too hard to connect the dots to see that the technology is trusted and proven for doing real-time characteristics on the farm. The need for sending samples will certainly lessen, and maybe eventually disappear altogether.”

VeriGrain’s grain sampling system was awarded the prestigious AE50 Award for product innovations in the areas of agricultural food and biological systems.