Researchers from Agriculture and Agri-food Canada are working with nanotechnology to open new doors against crop pest insects.

Today’s pesticides often struggle with non-specificity, said Justin Pahara, research scientist and principal investigator in the Nano Lab at the federal agriculture research station in Lethbridge, Alta. While there are emerging products that target specific biological vulnerabilities of a given pest, for the most part, “the way they work now is they’re broad spectrum … when you spray them, they impact different other species, whether it is a plant, insect or fungi,” he said.

Read Also

Ship’s turning for gene-edited crops

More and more countries have decided that gene-edited crops will be treated the same as conventional plant breeding.

WHY IT MATTERS: Ag companies are increasingly looking for pinpoint accuracy for targeting specific pests, allowing better control and less risk to farm-friendly insects like pollinators or natural predators.

Nanotechnology might help farmers of the future reap the pest control benefits of chemical application, without some of the environmental or farm productivity downsides, if the Alberta researcher has anything to say about it.

Chemicals tend to target the nervous system of insects. Common insecticide imidacloprid, for example, mimics the toxic impacts of nicotine at the molecular level, applied at doses too low to impact humans, but which are still deadly to insects.

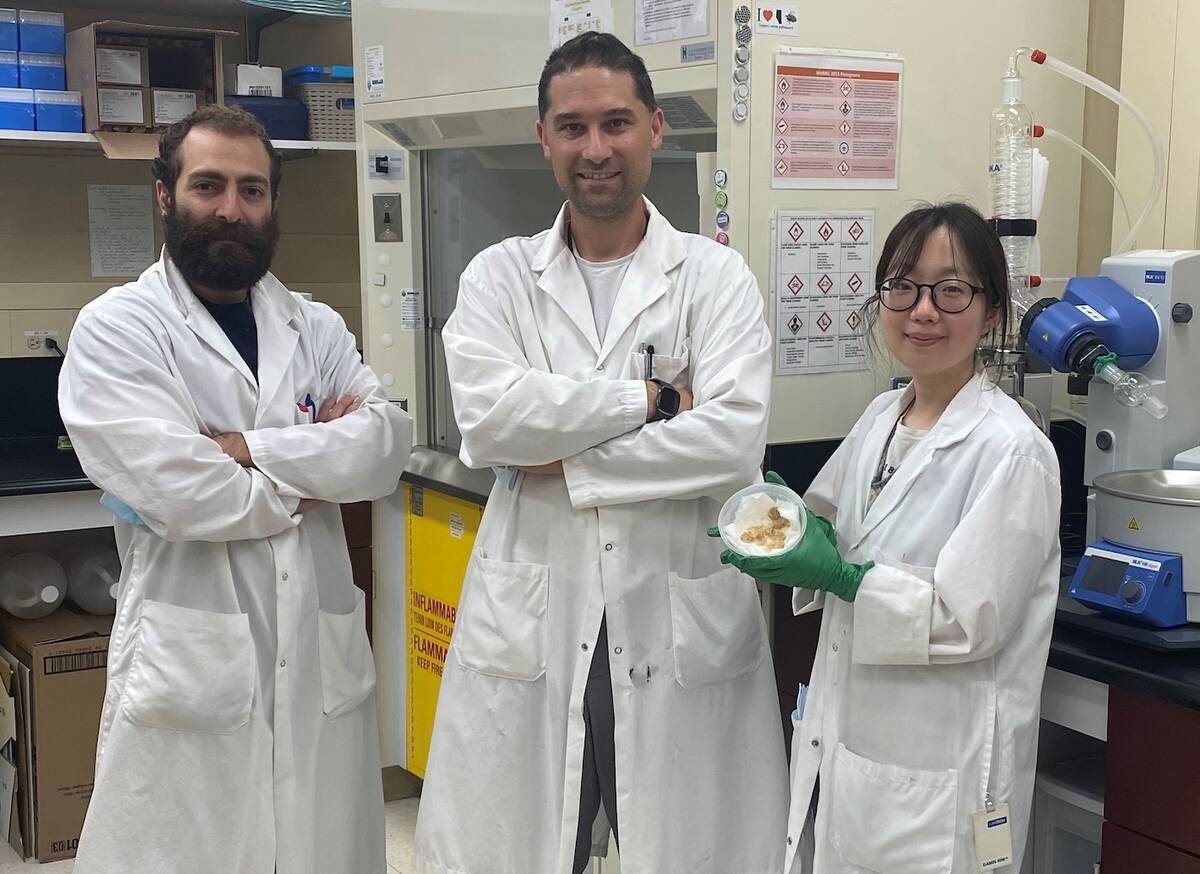

Pahara and his team of five research assistants, however, are working on new crop treatments which target pests at the genetic level. Their first targets: lygus bugs and cutworms.

“DNA is specific to a particular organism,” said Pahara.

“When you go across a species, from a honeybee to a cutworm, their genomes are quite different. And this gives us the opportunity to leverage that through a couple different ways.”

The project is one of a new wave of products under development that look to RNA.

“RNA is the intermediary between DNA and proteins, and there’s a very special pathway mechanism that happens in cells,” Pahara said. “If you put a small piece of very specific RNA into a cell that’s foreign to that cell, there’s a good chance the cell will recognize it as foreign, and then it will act similarly to an antibody and an immune response. It’ll use that little piece of DNA that it found to target and cut up more of the RNA it sees.”

RNA, for example, is a critical component of most viruses.

“It’s highly technical, but basically, we’re targeting specific genomics or nucleic acid fingerprints within each (insect),” Pahara said.

In crop protection, RNAi, or RNA interference technologies, are already looking to influence certain gene expression specific to certain organisms, turning pest control into more of a surgical sniper operation than a blanket chemical bombardment. Researchers have begun looking for RNAi solutions to a wide range of agricultural pests, from diseases like sclerotinia, to insect pests like flea beetles or parasitic varroa mites.

Most of the appeal of RNA-based control comes from its novelty. It opens a new, non-chemical methods that pests have yet to begin developing resistance to, keeping more management tools viable for longer, reducing farmer reliance on chemical products, and also potentially dodging pesticide limits that can hinder trade.

“We need new crop treatments,” said Pahara. “We need them to be less toxic.”

If crop treatments are determined to be so specific that they don’t harm other insects, let alone humans, that allows for a lot more freedom of use, he said.

The age of nano

The research team, which includes students from the University of Lethbridge, the University of Calgary and the University of Alberta, are developing methods to track how nano-substances move into and through insects so they can better choose which bits of RNA to target for control of that insect.

The team did some work at Canadian Light Source, based in Saskatoon. The facility is based around a synchotron — a particle accelerator which accelerates electrons to the speed of light. Those electrons are then diverted and converted in high energy X-rays. These X-rays go into little rooms all around the Synchotron ring. This, in turn, can be used for highly detailed, microscopic imaging.

To investigate treatments against lygus bugs, the team used different beam lines, including the BioXAS beam.

“This one is cool, because it allows you to image something just like you would in a camera,” said Pahara.

But unlike a camera, imaging based on BioXAS data gives a full spectrum of information, such as revealing the chemical elements present in each pixel.

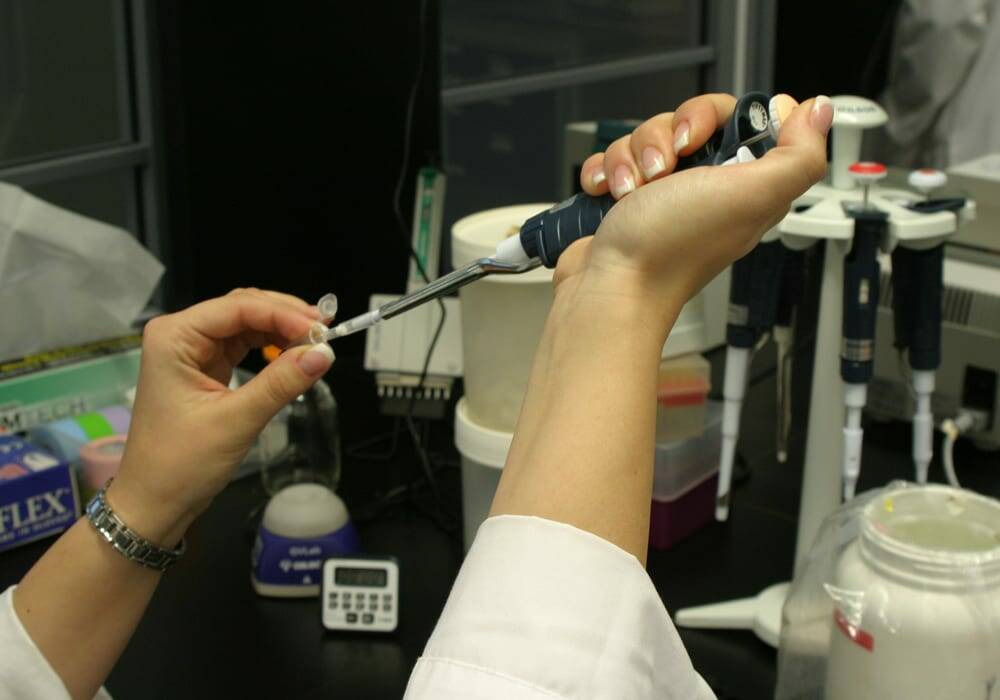

The researchers treated insects with nanoparticles and nucleic acids and then, after exposing them to imaging, were able to see where those elements went within the insect’s anatomy.

In order to get a 3D image (BioXAS data is usually presented in two-dimensions), each insect was cross-sectioned into 40 slices. Each of those slices was imaged, and the data combined to form a full 3D picture of that insect.

“We had this three-dimensional insect, where we could see where all the elements are in it. That’s important because it gives us three dimensions of spatial resolution, so we can see where stuff is going,” the researcher said.

Defence to the defence?

But what about if the insect pests start to adapt to this control avenue as well? If an insect’s DNA changes to the point that the RNA-based solution isn’t effective, Pahara believes the crop treatments can be adjusted.

“It allows us to tweak and reprogram them easily, whereas with the old generation of treatments, they’re just small chemicals. You just can’t tweak them,” he said.

The research has now been expanded to fusarium head blight and kochia.

“We’re developing methods that work for screening, and we’re starting to ramp up screening, which means we’re testing lots of different kinds of formulations that have different nano materials in them. As we screen thousands of different systems, we’ll know the ones that may work best,” he said.

After material has been tested in the lab, it will eventually move to greenhouse trials and field trials.