Sustainable protein for livestock feed commonly brings to mind pulses and other crops. A facility coming to Saskatchewan plans to make livestock feed from black soldier flies.

In late June, agricultural technology firm NRGene Canada announced that its North American Insect Centre in Saskatoon will open July 30. The facility was developed in collaboration with Swiss technology group Bühler. It aims to continue research and development of soldier fly strains.

“Western Canada is a hub for agriculture,” said Masood Rizvi, general manager of NRGene Canada, on the choice to put the centre in Saskatoon. “There’s lots of crop byproduct in Saskatoon. Saskatoon also has lots of agriculture companies and processing. Everything is happening here.”

Read Also

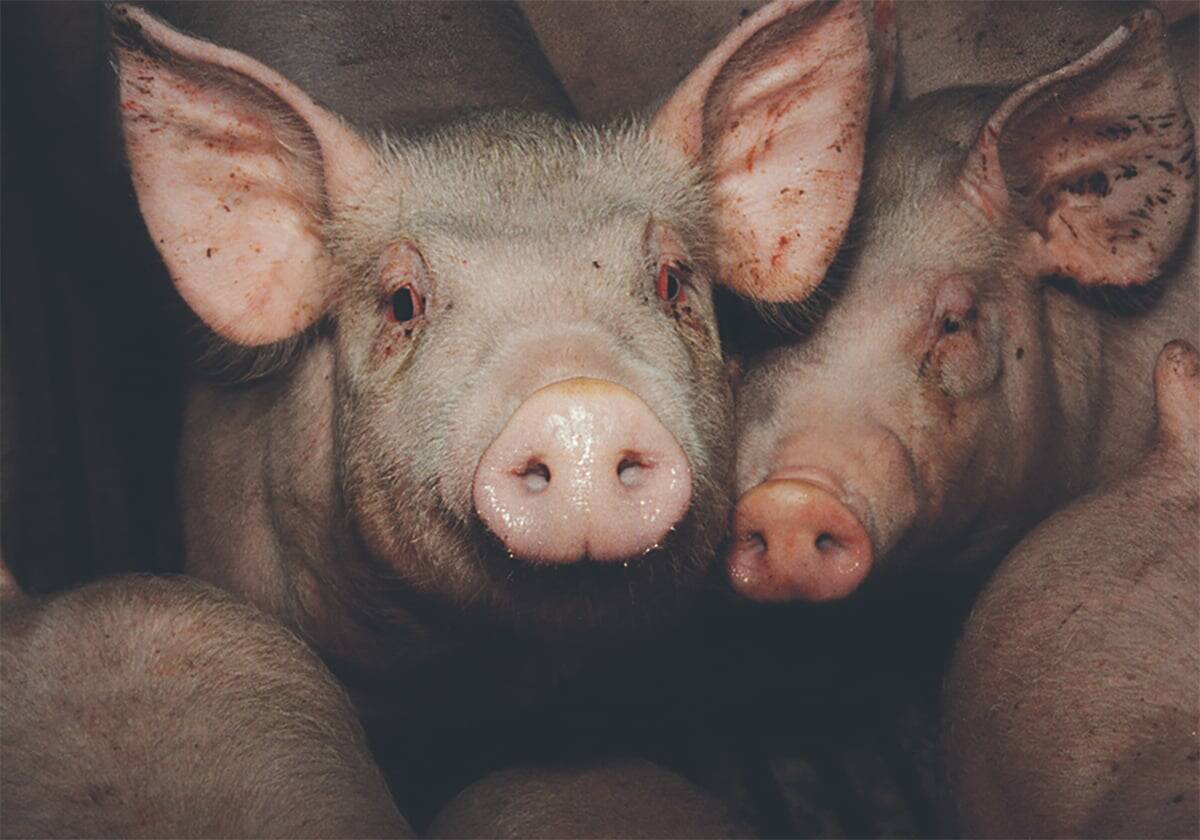

Scientists discover cause of pig ear necrosis

A University of Saskatchewan team, through years of research, has discovered new information about pig ear necrosis and what hog farmers can do to control it.

Why it matters: A Saskatchewan facility will promote insect protein as a sustainable source for livestock feed.

Black soldier flies feed on decaying organic matter, making them a popular choice for composting or reducing manure. By using agricultural byproducts to feed them, NRGene hopes to close part of Saskatchewan’s nutrient loop.

The flies are a primary focus of research at NRGene. The company has used data analysis and artificial intelligence to develop better genetics — flies with larger larvae or reduced hatch time.

Bühler installed a climate-controlled larvae growth chamber that simulates industrial conditions. So far, it has been used in preliminary trials. Larvae growth and development results have been promising, a June 18 press release said.

The larvae take four days to hatch, spend five days in the nursery and then seven days at agri-waste producers eating before being harvested. From hatch to harvest takes 12 days, according to the company, down from the roughly two weeks seen in other black soldier fly operations.

The original length of a full cycle, from egg to mature fly, is 42-45 days.

The company is still looking to advance and understand the flies. With genomics and phenotyping, they expect to tailor insect lines to customer needs for things like improved feed conversion rates.

Andreas Baumann, head of market segment insect technology at Bühler, said the Saskatchewan facility will benefit clients. It will offer workshops, training sessions and seminars to educate on the benefits and best practices of insect protein production.

“It will serve as a meeting place for our clients, particularly those from North America, to collaboratively optimize insect plant operation,” he said in the press release. “Together, we can fine-tune both biological and technological aspects.”

Outreach is a secondary purpose of the centre, said Rizvi. The company intends it to be an educational opportunity for interested parties as well as customers. While customers will likely be interested in assessing black soldier fly varieties, operational parameters, and practices for industrial efficiency, other visitors will seek to understand the business concept.

“People want to know more about how we do insect farming, because it’s like another level of farming,” Rizvi said. “So, we want to really make sure that people come from the different industries, or students who want to build an understanding … and if they want to do the workshops, they can.”

Gaining attention

Firms that cultivate black soldier flies for the feed market are popping up internationally. In 2022, the Co-operator visited one such fly farm in Denmark. That business fed food industry waste to the insects and converted larvae into protein meal.

When dried, larvae can be up to 50 per cent protein.

In terms of regulations, its a comparatively new idea. Rule changes in Canada and Europe have opened the door for insect-based animal feed in the last eight years. Past product approvals in Canada have included pet food and food for fish, hogs and poultry.

A search of feed products registered by the Canadian Food Inspection Agency returns a number of companies with registered products covering black soldier fly larvae or products processed from larvae, such as oil.

This story has been updated to clarify the length of the harvest cycle of black soldier fly.