Humans need zinc. It’s essential for our immune systems, wound healing and nerve function, to name a few.

However, our bodies don’t produce it naturally. We rely on food or, in the modern world, supplements to get it.

A lot of people don’t get enough. Neither do our crops.

Read Also

VIDEO: Manitoba’s cabbage seedpod weevil explosion

Crop pest could pose a big problem for Manitoba canola growers in 2026 if last year’s population jump wasn’t a fluke.

“There is an assumption that one-third of the world population consumes less than ideal zinc, because, basically, the products we eat are not enriched enough with zinc,” said Rodrigo Coqui da Silva, a soil science and agronomy researcher at the University of South Australia.

It’s his hope that fertilizer technology can help address the deficiency.

Why it matters: An Australian university is looking at ways agriculture can help address a lack of zinc in the global food supply.

According to the International Zinc Association, over 50 per cent of world soils are zinc deficient. The result, it argues, is poorer crop performance and decreased nutrition.

Addressing the problem is not as simple as laying down zinc at the same time as other fertilizer applications. There’s a known “very negative” interaction between phosphate and zinc, the Australian researcher noted —a big problem with phosphorus being a main fertilizer need of crops.

In most cases, zinc becomes unavailable to the plant when the two are combined in the same granule, due to reduced solubility of the zinc.

The issue hasn’t garnered a lot of attention amid the wide world of fertilizer research. While at the University of Adelaide, da Silva and his team decided to change that.

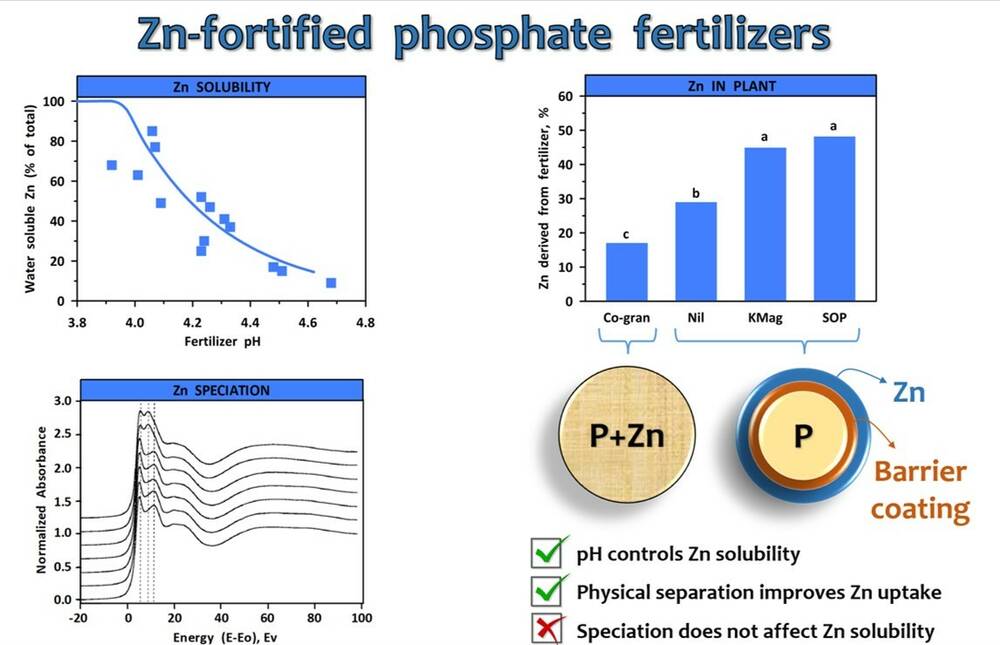

Their initial hypothesis was that the solubility problem was rooted in the form of zinc – zinc oxide, zinc sulphate, etc. After testing 14 different zinc types, though, it was determined that there was no relationship.

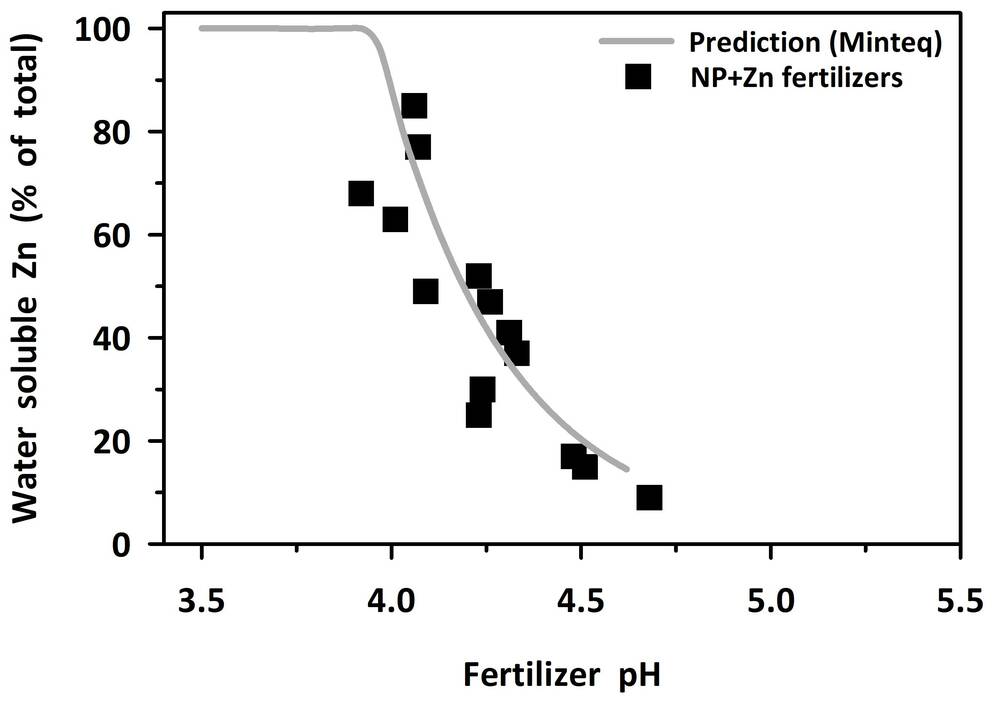

The team next looked for a way to increase zinc’s general solubility to allow for greater plant uptake. Building off initial findings and the knowledge that fertilizer pH levels were linked to zinc solubility, they established two potential methods: acidifying the fertilizer, or creating a physical barrier between the two minerals to dodge the problem entirely.

Results of Rodrigo Coqui da Silva’s research into zinc-fortified phosphate fertilizer. Photo: Rodrigo Coqui Da Silva

Zinc solutions

The first method is a simple addition to current fertilizer production processes, da Silva noted. A small amount of an acidic substance is sprayed onto the product during the granulation process. Da Silva called it a “single action improvement.”

“Decreasing the pH of the fertilizer will increase the solubility of that fertilizer,” he said. “And for the fertilizer industry, it’s very easy because they have acids all over the place. It’s even a byproduct — and the acid is very diluted, and it’s a very small quantity (used).”

This graph outlines the the relationship between zinc solubility and fertilizer pH. The more acidic

the fertilizer, the more soluable zinc becomes. Photo: Rodrigo Coqui Da Silva

The second method utilizes the same coating technology currently used for slow release fertilizers. In this case, the method would be used to separate the two minerals in a single fertilizer mix. The barrier coating would be applied to granules of phosphate, then zinc would be added on top of that.

The method offers zinc a chance to travel to the plants first and be taken up, before the phosphate negatively interacts with it.

“Of course, when you apply the fertilizers to the soil, they will mix again. But at least you give the opportunity to the zinc to diffuse further away before this interaction happens,” da Silva said.

Making it real

U.S.-based fertilizer firm the Mosaic Company partnered with the University of Adelaide, leading to the two methods already earning patents.

They have yet to be tested in natural field conditions, although da Silva and his team have tested them under greenhouse conditions.

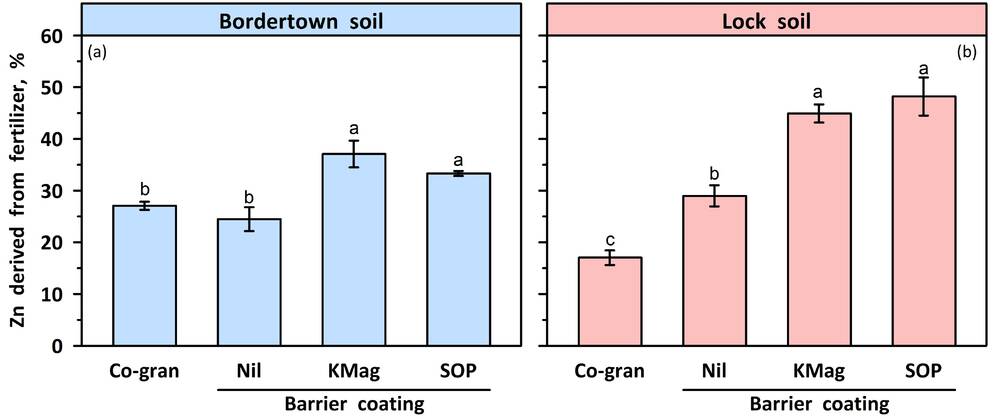

Within that controlled environment, the team could track the zinc compounds within the plant and analyze how much zinc was absorbed from the known quantities of fertilizer they had applied. The tests showed an increased solubility of zinc from the products they developed.

“We could know exactly how much came from the fertilizer – because zinc can (also) come from the soil or seeds and things like that,” da Silva said. “So when we use (our) technology, (nearly) 50 per cent of the zinc came from the fertilizer.”

When zinc and phosphate were co-granulated, only 18 per cent of the plant’s zinc came from the fertilizer treatment.

The percentage of zinc that a crop is able to absorb significantly increases when a barrier coating is added to the fertilizer. Photo: Rodrigo Coqui Da Silva

They tested four treatments. One was co-granulated between zinc and phosphate, as a control, and the other three tested different barrier coatings.

The controlled environment cannot adequately represent field trials, but it’s a strong start, the researcher said.

“Sometimes in the lab, on the kind of small scale, we can fix a lot of things but it’s not scalable,” he said. “So sometimes when they scale that up, it doesn’t quite work because of different reasons or it’s an economical decision.

“But in this case, we’re quite happy that we could understand the difference between these compounds … Then we created these two technologies to overcome that product (problem), and the industry is using that.”

Da Silva tends to stay out of the business side, but he knows there is further testing planned for the physical barrier technique, and the acidifying spray method is already in production.

Mosaic declined to comment due to the “proprietary nature of the project and ongoing internal reviews.”

They added that relevant details are publicly available within the patent documentation.