I was thinking, if there were several points that could make a big difference in today’s modern cattle production, what would those be?

Here are some that I hope resonate with producers.

There are still holes in many producers’ vaccination programs and one of the most critical is getting IBR and BVD protection into our breeding animals. Abortions from these diseases are very rare, but make sure good BVD protection occurs before breeding, as infected calves shed virus in the cow herd and in feedlots and that increases respiratory disease.

Read Also

First-time pig mothers may need more lysine

Lysine feed recommendations may fall short for gilt pregnancies when it comes to making sure the mother pig can produce as much milk for her piglets as possible

The U.S. has a much higher incidence of these because of all the smaller cattle herds that don’t get vaccinated. But we still need to work on getting calves vaccinated for these same diseases as well as the respiratory bacterial pathogens such as mannheimia, histophilus and pasteurella.

We as veterinarians must review vaccination protocols with you, our clients, to give the Canadian cattle herd the disease protection it needs. This single handedly should reduce lots of antimicrobial usage, as well. Pre-immunization and vaccinating calves for clostridial disease is almost always given but we need to ensure tetanus and redwater are included when we need it.

Almost as important as which vaccines to use is how to administer them properly.

Anyone who knows me knows I stress storing vaccines properly. Only mixing as much modified live vaccines as you can use in the next one to two hours is advisable.

Also, if giving two vaccines, make sure they are at least a handbreadth apart. Label each syringe with which vaccine it is carrying. (New guns often have different-coloured ends as not mixing products in different syringes is critical.)

I am convinced some disease outbreaks occur because vaccines were frozen or heated or administered on top of one another. This can destroy or greatly reduce efficacy so then they don’t protect fully or at all. You all pay very good money for vaccines, so establish the right protocols, and get the timing of administration as good as you can, and look after them properly to maximize protectiveness.

Your veterinarian will most often prescribe NSAIDs for the reduction of pain for castration and processing, tough calving, and all surgical procedures.

This is becoming accepted practice at spring processing and several products are available with many means of application. The beef code of practice has accelerated this process by concentrating on the animal welfare side of producing cattle.

I believe cattle producers are way ahead on this and realize the value to the health and well-being of the calf by using these NSAIDs.

The biggest economic return in today’s cattle production is implanting.

It may take some practice to perfect doing it but think of it every time you’re working on calves or culling cows. These are the two most opportune times in the cow-calf industry to implant.

If you are marketing into some type of no-added-hormone program, that is fine. Just make sure you are getting more returns per pound to justify this loss in growth you sacrifice by not using implants.

Implanting takes a bit of practice to do well. It requires good head restraint and always put the implant gun through the cleaner prior to implanting the next calf.

Another big economic return is controlling both internal and external parasites.

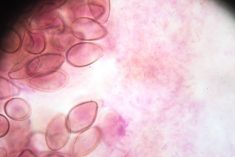

There has been resistance seen out there to certain parasiticides for both internal worms and external parasites (such as lice and flies). Have your veterinarian help develop better timing, choose what products to administer, and check fecal counts for worms to establish really what is in our herds.

There is a huge variation out there plus there are differences between species. Goats or sheep have higher minimums before we deworm. There may come a time where fecals may be required before dewormer can be purchased to administer. For lice, we may need to tag team with other products to complement the ivermectins. Or cattle oilers may be the answer.

Spend a little more management time considering when, how and with what products we need to tackle lice control. For flies, we also need to wait until levels get to the optimum levels to treat in the summer with oilers or pour-on products approved for lice.

Every producer, in my eyes, can always look at streamlining their handling system as well as working on low or stress-free handling of their cattle. Any time that prods are used too much, assess why that is so and work at ways to correct it. I have preg checked in many great handling systems where prods are almost never necessary. This also avoids feet and leg injuries from too rough a handling. Cattle will become easier to handle with each subsequent handling.

I hope some of the above points may provide some clarity and benefit as to what is generally happening in the cattle industry. I would encourage any of you to keep abreast of any articles in producer or breed association magazines.

Also, for the latest practical developments and research the BCRC seminars online are fantastic, in my eyes — very objective presentations that will greatly help producers.

We can always learn and implement new things that will help our operations.