Ear tags are typically easy to come by, but in an ag sector struggling with supply issues, producers and industry say those tags, and other critical supplies, are notably scarce.

Why it matters: Livestock producers are having trouble sourcing basic supplies throughout the industry.

According to a statement published on the Canadian Cattle Identification Agency (CCIA) website, tag manufacturers have run afoul of a flagging value chain. Suppliers have reported a lack of raw material, as well as absenteeism, the statement said, a common story as COVID-19 continues to roll through the workforce.

Read Also

Manitoba crop insurance expands wildlife coverage, offers pilot programs

New crop insurance coverage is available to Manitoba farmers.

The CCIA further said that its distributor was receiving shipments, “periodically.”

“But as the busy calving season is upon us, demand is exceeding availability for some products,” the statement read.

“It’s not just one thing; it’s many things,” CCIA general manager Anne Brunet-Burgess said.

In addition to the pandemic and general stress to the supply chain, two manufacturers used by the CCIA are located in Texas, where shipments were delayed due to atypical winter weather, she said.

The agency has introduced a cap on order sizes for some tags.

Brunet-Burgess maintained that there are enough tags available for producers, although they may not get their preferred tag option. A significant amount of inventory also rests in the hands of dealers, she added, even if the CCIA itself has fewer tags for direct purchase.

“There’s no reason why someone would not be compliant in moving animals without tags,” she said, “but it may require to look in different places and, again, just by popularity, some brands have run out or are back ordered.”

Roger Mangin of Inwood Feed and Supply said he has added a second supplier in an effort to source more tags. That has significantly increased his workload, he said.

“For the storefront, we don’t know what’s coming,” he said. “Some of the most common things that should not be on back order, are on back order.”

He will likely have to shift order patterns to meet the demand, he added, “which unfortunately will probably cause some price increases, because if the ear tags keep on being hard to get until the end of calving, I’m going to order next year’s ear tags already in July. That means I have to carry some of that inventory for nine months.”

He, like many others in the industry, pointed to issues with trucking.

As of the third quarter last year, the transportation sector sat at a record eight per cent job vacancy rate, according to Trucking HR Canada.

The CCIA is still urging producers buying directly from the agency to place their order, even if the product reads as “back ordered.” Doing so will ensure the producer’s place in the queue.

Cam Dahl, general manager of the Manitoba Pork Council, says their industry has similar problems sourcing ear tags.

“There have been issues,” he said, noting that, like the cattle sector, there have been production problems with the manufacturer.

Mangin said he has not seen other shortages, although he began ordering extra inventory in December as a precaution.

Feed

Supply issues have been a major story in the pork sector in 2022. In mid-January, the Manitoba Pork Council already noted serious delays of live animal shipments to the U.S., along with shortages of soybean meal from south of the international border.

“Some of this is pandemic related,” Dahl said, “and I would put things like the ear tags in that category as this is the impact of the pandemic on general supply chains. And then some of this is ongoing, endemic supply issues that have been made worse by pandemic-related issues.”

Long-term trucking shortages, in particular, have been a sticking point for the pork sector, as is a general labour gap in the pork sector.

Sourcing soybean meal has become difficult province-wide, “and there have been ongoing cancellations and there have been ongoing delays in shipments that are causing producers to shift rations,” Dahl said. “Which, of course, is expensive.”

Feed supplies in general are tight, he added, increasing the cost.

There have been similar issues sourcing feed additives like lysine, Dahl also noted.

There have been some issues accessing purchased feeds like feed pellets or dried distillers grains (DDGs), Carson Callum, general manager of the Manitoba Beef Producers, said.

Last year, historic drought devastated hay and forage supplies in the province, increasing reliance on alternate feeds.

“We know that feed availability overall has been a challenge for producers, especially here in Manitoba and producers are really having to expand their reach a bit to find some other products that they may not have used in the past,” Callum said.

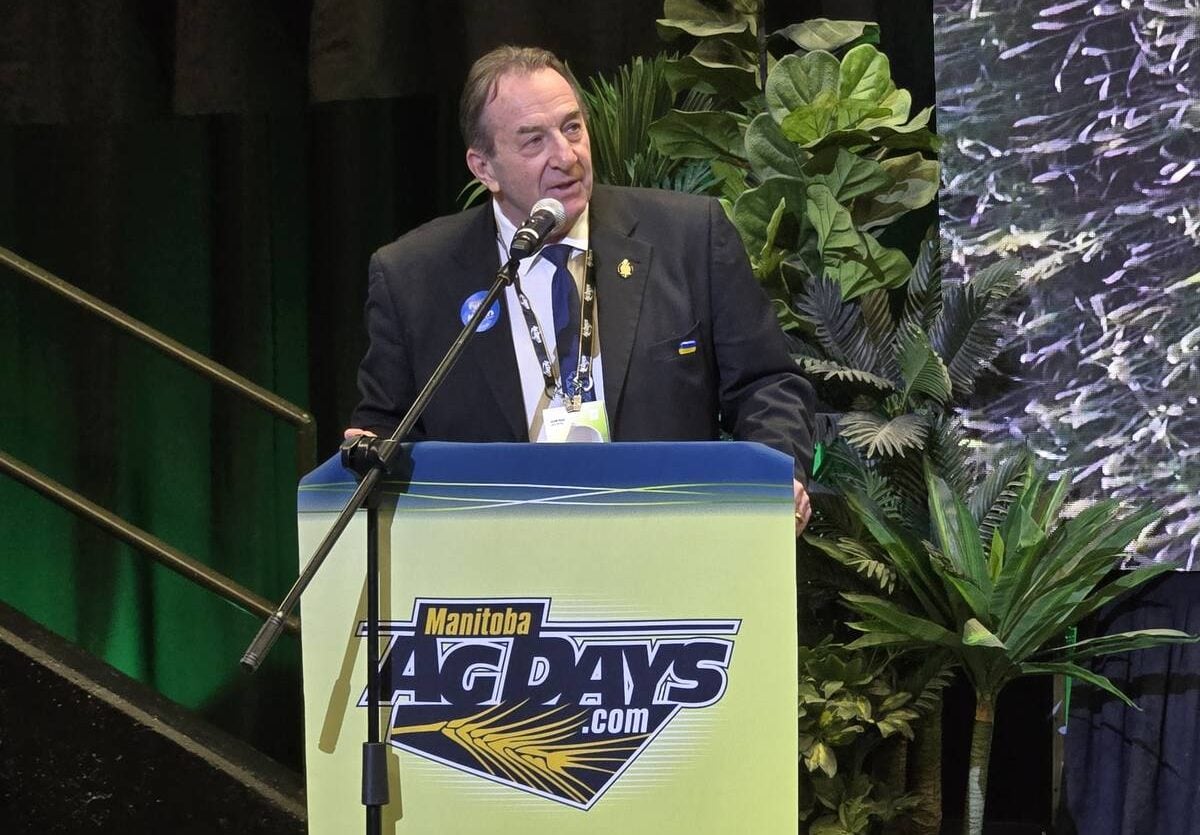

Bill Campbell, president with the Keystone Agricultural Producers and a livestock producer, says he has experienced those issues first hand. Feeds like screenings and DDGs have been hard to get a hold of, and what is available is expensive, he said.

Mangin said he has not had an issue keeping feed in inventory, although the cost of products like complete feeds with grains have skyrocketed.

Campbell also pointed to issues with DDG, corn and soybean meal shipments coming into Canada.

“Probably since before Christmas, those issues have been apparent,” he said.

He has not heard of any catastrophic feed shortages, he said.

“There may be individual situations where you’re out of what you’re used to for a week or something like that, but it is a different world and a different environment that we’re dealing with on all aspects,” Campbell said. “Our inputs, our feeds and cost. (It) just brings a whole level of uncertainty with our practices.”