A project to turn canola meal into home heat through pelletization is ready for its next step.

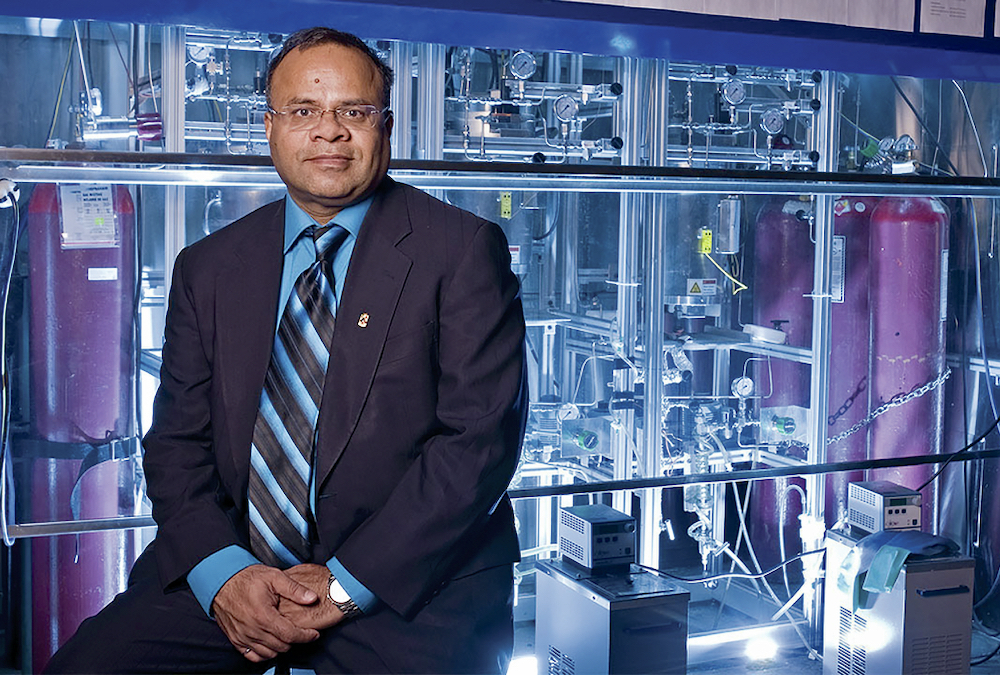

Ajay Dalai, a Canada Research Chair at the University of Saskatchewan, says they’re now ready to scale up pellet production and enter commercialization.

He says the product could find a market as an eco-friendly replacement for coal and natural gas for both heat and energy.

“Eventually, the world is going to phase out coal because of pollution,” said Dalai in a media release from the University of Saskatchewan’s College of Engineering.

Read Also

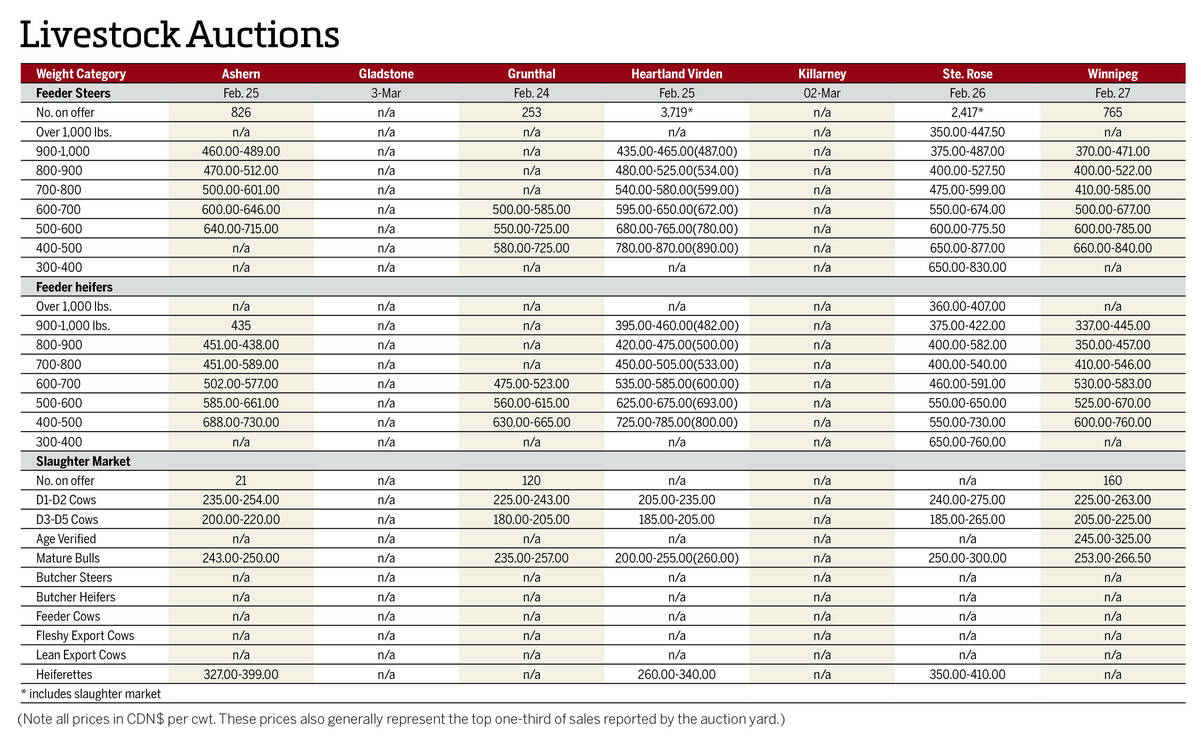

Manitoba cattle prices, March 4

Chart of weekly Manitoba cattle prices.

In 2019, Canada produced over 18 million tonnes of canola and the oil extraction process leaves behind canola meal, which is about 60 per cent of the original crop by weight. Some canola meal is exported and about 40 per cent is fed to livestock. The remainder is what Dalai sees as potential biocoal. The challenge is to produce high-quality pellets suitable for storage and transportation to facilities where it can be burned to produce heat and power, he said.

Dalai and colleagues have been using computed tomography techniques at the Canadian Light Source at USask to examine lab-produced pellets. When he first visited a synchrotron in the U.S. about 25 years ago, Dalai saw things nobody can see with the naked eye.

“It ignited a passion in me to apply these techniques to biomaterial,” he said.

“We need to know how they look on the inside, what the structure looks like,” he said.

That allows the researchers to assess the impact of different additives and different amounts of water on the mechanical strength of the pellet and the amount of energy produced when it is burned.

His latest research demonstrates the optimal amounts of various additives that serve as binders and lubricants to create a canola meal pellet that will not absorb too much moisture or crumble when stored or transported. It is a recipe that is now ready to be tested in the real world, Dalai said.

“We’ve been working for five or six years on this project. It’s time to produce the pellets on a large scale to see the consistency of the product.”