Glacier FarmMedia – The pre-harvest season is a good time to think about best practices around grain bin safety. Sounds like one more set of things to do on top of about a million others, right? Not necessarily, said a farm safety specialist.

Those already taking action to minimize grain spoilage are also eliminating safety risks, said Robert Gobeil, a health and safety specialist with the Canadian Agricultural Safety Association. Well-conditioned grain is less likely to crust on bin walls or create ‘bridging’ — both of which can result in serious injury if it’s necessary to enter a bin.

Gobeil has other examples, but prefaces them with a disclaimer: Basically, don’t count on generalities. Know your commodity-specific best practices when it comes to conditioning, cycling and monitoring.

Read Also

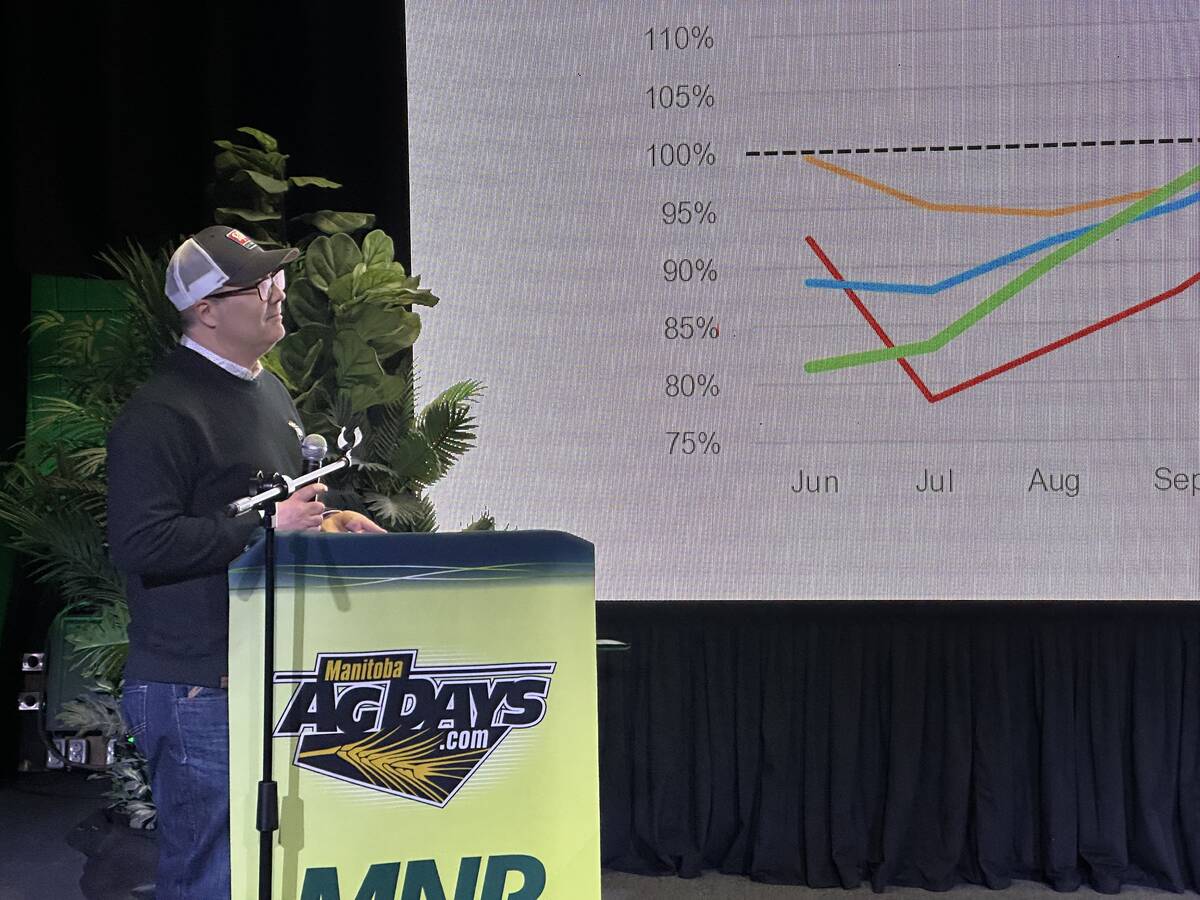

MANITOBA AG DAYS: Don’t wait to buy fertilizer, farmers warned

Higher fertilizer prices likely ahead, says Ag Days speaker. Farmers waiting until spring to buy fertilizer might end up eating the cost.

“That’s where talking to your commodity groups, your ag associations, things like that, can really be a benefit,” he said.

“When the bin is empty you want to check your mechanical systems to make sure bin sweeps, augers, chutes and aeration systems are maintained and working properly. That way you know you can maintain the product once it is in the bin.”

Check ladders for defects.

“Falls from heights generally do not have a very good outcome and we just want to make sure that if we do need to access the top hatch of the bin, or if we need to enter the bin, that we can enter safely,” said Gobeil.

Also think about children on the farm and those who might visit.

“I would recommend, especially nowadays, to have a locking mechanism on the hatch just to prevent any unauthorized entry into the bin,” he said.

Moving grain around by loading it into a truck and back out again can be a key tool in grain spoilage prevention. However, it can also be time-consuming, especially during harvest season.

Although cycling should be done regularly, Gobeil said even a little bit of grain movement helps fight the ever-creeping threat of spoilage.

“Even just one quick load would make a big difference in keeping the grain in good condition,” he said. “Not everybody has even a spare hour out on the farm but just between other job tasks you may find some time and make a point of doing it.”

Regular monitoring is also critical. Today there’s a whole industry of cables and sensors intended to help growers identify problem spots.

Gobeil said he can only recommend concepts and not specific products, but he is intrigued by sensors that monitor bin conditions and send information to an app in real time.

“From what I understand, some of these technologies are even getting to the point where if things start to heat up or if there’s a spike in the humidity in the bin, you might even get an alert on your phone.”

Of course, no app can do the dangerous task of entering the bin and knocking out crusted or bridged grain.

“If it does go out of condition, there is no easy fix. Sometimes it’s a matter of tinkering around with a bar from up above (to knock out crusted grain). With the larger bins it might be a matter of using internal ladders or stairwells. Hook up a set of fall protection equipment so if you do step on the grain and it gives way, you don’t get entrapped.”

Wearing personal protective equipment (PPE) around spoiled binned grain depends a lot on the extent of the spoilage and how close one needs to be. However, rodents and other pests are another reason to wear it.

“With mice, there is concern of hantavirus,” said Gobeil. “There are also concerns about pigeon droppings and insect infestation. All of these things can spoil the product inside the bin as well as cause some fairly serious health concerns potentially.”

Gobeil recommends a properly fitted, double-filtered half-mask. The exact kind of filter may depend on the kind of hazard involved.

But what about exposure to spoilage itself? No one wants to breathe in mould spores that can make them sick.

“If someone were to need to go in the bin because the grain is out of condition, I would strongly suggest wearing some appropriate PPE such as coveralls and using a P100 double-filtered half-mask respirator. At a minimum I would recommend an N95 mask.”

The safety best practices in the world won’t help if they’re not communicated to those working on the farm. It might be worthwhile to do a quick review of proper procedures going into the busy season, said Gobeil.

“As things gear up, I would recommend taking a look at whatever safety documentation you have in place on the farm already. You want to train the people performing those job tasks those procedures and emergency plans.”

– This article was originally published at the Alberta Farmer Express.