The market for hemp fibre may be on its way up again and Jeff Kostuik of Verve Seed Solutions says it’s based on a part of the plant that used to be considered waste.

At a crop demonstration for the Parklands Crop Diversity Foundation in Roblin, he pulled apart a hemp stem and showed the fibrous, almost woody core. It’s called the hurd.

“This is the strong part, the super absorbent middle part of the plant. This was actually a byproduct seven years ago but it’s what’s driving the fibre market right now,” said Kostuik.

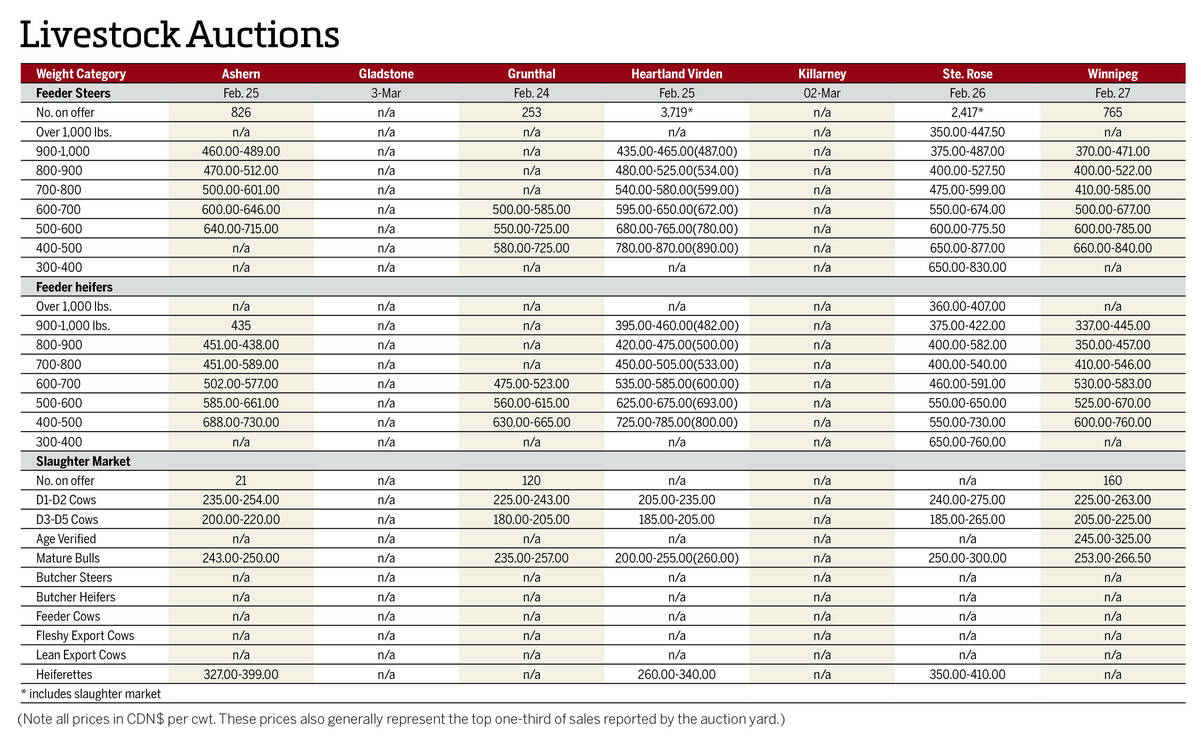

Read Also

Manitoba cattle prices, March 4

Chart of weekly Manitoba cattle prices.

Hurd is used to make hempcrete for the construction industry. Hempcrete a bio-composite material, almost like concrete, made from a hydrated lime binder mixed with processed hemp hurd fibre. The process starts by separating the hurd in the centre of the hemp plant from the “bark” on the outside.

“The process of separating those two is called decortication,” Kostuik said. “The crop is laid on the ground, the microbes come in and eat the pectin and the lignin that hold these fibres together. Then it runs through a hammer mill. essentially, separating them.”

The fibre and lime are mixed and pressed into a hard block. These blocks can be stacked to make something similar to a cinder block wall. The material may also be mixed with less moisture to become a fibrous fluff that can be sprayed into a frame, almost like plaster.

Unique properties

Hempcrete isn’t used like concrete because it doesn’t have the rugged strength. It is not suitable for bearing walls but it does have insulating value and it doesn’t mind water.

“It’s like a thermal wall,” Kostuik said. “If the house gets flooded, once the water recedes, you don’t have to rip out all the drywall. The house just dries out.”

This is especially important in the southern U.S. states, where hempcrete is popular for building low income housing. The non-weight-bearing walls can be built with the blocks or sprayed in fluid form into a stud frame. It can also be used to restore older stone walls.

This has caused a sudden demand that many hemp growers can’t fill. Many are servicing the new CBD market, producing a cannabidiol that doesn’t contain THC, which is used in medicinal applications. Farms producing CBD are small, 10-acre orchard operations requiring intense management.

“So, you’ve got all these little 10-acre farms scattered throughout the U.S. and then the fibre market comes and they want all this fibre and they’ve got to deal with 100 of these 10-acre farms,” Kostuik said.

“They come up to Canada. We’ve got a grower just outside of Portage who’s growing 4,000 acres of hemp for a fibre one stop shop and they’re very interested in what we’re doing here.”

Developing

Kostuik says Alberta is leading the way in fibre processing. Canadian Rockies Hemp Corporation in Bruderheim, near Edmonton, has contracted 15,000 acres of fibre hemp. The Hemp Sense plant in Gilbert Plains is taking another run at fibre hemp as well.

Hemp Sense produces more than fibre. It is able to work with CBD hemp as well as hemp grain — and the plant’s versatility creates a challenge.

If hemp grain is desired, short plants are needed so a combine can handle it. For fibre, taller plants with lots of tissue are best.

“Hemp is a photoperiod sensitive crop,” Kostuik said. “We get more height and more vigorous growth out of a hemp crop the further north you go.”

The photoperiod refers to day length, and summer days in the northern parts of the province are long. That means hemp in the Manitoba Parklands will grow a lot taller than hemp grown in Kentucky.

Kostuik says growers should identify the desired market before planting. The crop performs according to its geography.

“So, it is a challenge and when you get to a plant stature of 16 to 17 feet, it can be a challenge to harvest it and you need specialized equipment at that point.”

The Europeans have equipment with dual-cut combines to harvest really tall plants. The header sits high enough to combine the hemp heads, while directing stems into a type of forage processor.

In Manitoba, the tall plants may be good for fibre but not for grain because of the equipment. Cutting with a sickle mower or a disc bine could work, however, if it’s properly adjusted.

“Another issue, of course, has been the stability of those varieties,” Kostuik adds. “In Canada we have a program where you have to purchase certified seed and one of the reasons is that hemp is a very strong pollinator. The pollen will flow and be dispersed for miles and miles and miles.”

Hemp should be treated like an oilseed in the rotation. It’s another host to sclerotinia but none has yet been seen in Canadian hemp fields.

“I’ve never seen a crop failure in Canada because of sclerotinia but I was at a presentation in Wisconsin and a guy showed me a picture of a complete disaster because of their higher humidity and moisture,” he said. “So never say never, is what I learned from that one.”

The bottom line is that there are new opportunities for hemp, which is good news for growers.

“I’ve been doing it for a long time and every year there’s ups and downs just like every other crop and market but, once again, I kind of feel excited about what’s coming down the pipe for hemp,” Kostuik said.