A technique used to produce decaffinated coffee could be coming to a canola crusher near you.

It uses carbon dioxide gas under high pressure and low temperature to extract 99.9 per cent of the oil from the canola, leaving behind a pure meal that could be utilized in food-grade applications.

It’s also used to decaffinate tea and produce essential oils, but this is the first time anyone’s looked at using it for canola processing in North America. The hope is it will help increase demand for and use of canola, make processing more sustainable, and eliminate the need for solvents in the extraction process.

Read Also

Ship’s turning for gene-edited crops

More and more countries have decided that gene-edited crops will be treated the same as conventional plant breeding.

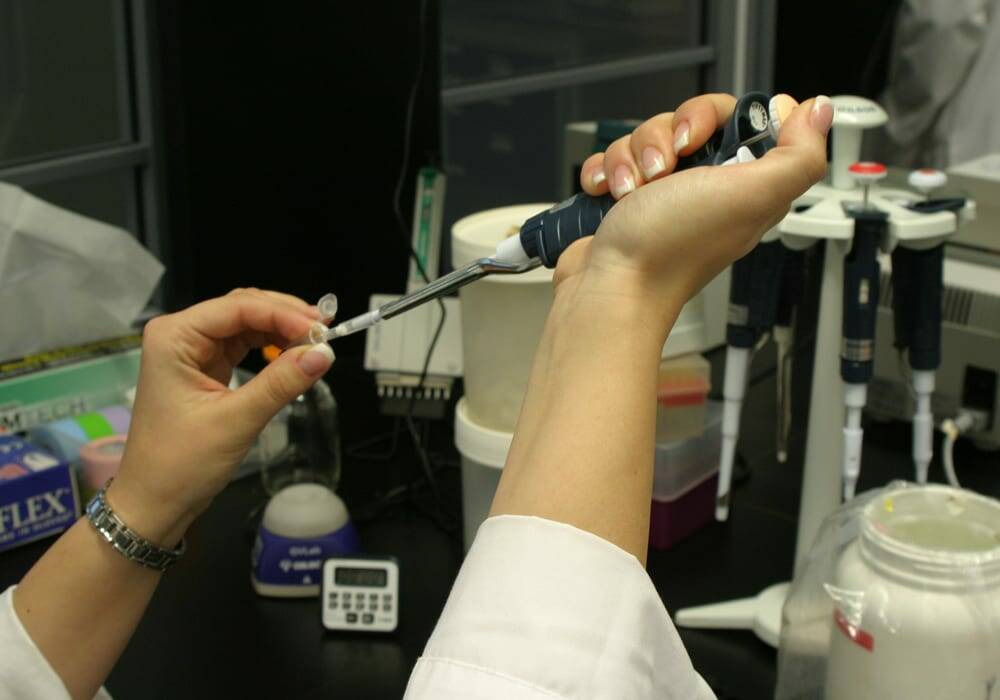

The work is being conducted by Nazanin Vafei, a University of Manitoba postdoctoral researcher at the Richardson Centre for Food Technology and Research. She’s the recipient of a Mitacs Innovation Award from the national non-profit research organization, and her work on canola oil extraction is what won her the honour.

The secret to this technique lays in the area between gas and liquid carbon dioxide. As the gas begins to convert to liquid form, it enters what’s known as the super-critical phase, where it can’t be clearly distinguished if it’s a gas or a liquid.

“The CO2 gas turns from gas to the super critical mode,” she said. “So in this situation, the super critical CO2 has the ability of the solvent… so it can extract the materials, like oil.”

Why it matters: Vafei’s method results in extremely pure canola meal, which can be used in plant-based foods. With growing global trends, this improved canola meal could open new markets and increase the crop’s value.

To ensure even extraction, Vafei utilized “anti-channeling agents” such as glass beads that are added to the extraction column. These agents combat the preferred pathways that the CO2 creates which would cause an under extraction, and as a result improves efficiency as well as the oil yield.

In her preliminary research, she didn’t find any previous research that had such a complete extraction of oil without a solvent. The only one that came close was a technique of using a cold solvent, which resulted in a 90 per cent extraction.

She said it can also be applied to other oilseeds and plants, as well as for the extraction of antioxidants from various biological materials.

But the most important takeaway is the purity of the canola meal, not just because of 99.9 per cent of oil being extracted but also since there are no additional materials such as solvents. With the typical methods, sometimes solvent residue will remain on the canola meal. There’s no such residue or remaining material with Vafei’s method.

“After the extraction is completed, we just depressurize the system and the CO2 comes back – it comes out from the samples (of canola meal) and goes back to the system,” she said.

This approach is great news for food processors, who often don’t have uses for canola meal because of solvent residue or too high oil content. The potential for the product is huge, since the meal contains a protein value of 40 per cent as well as essential and non-essential amino acids, making it a well-rounded source of nutrients.

“The canola meal is useful for plant-based protein products,” she said. “So, because we didn’t use the solvent… the protein quality is saved, and the phenolic compounds (are) preserved because of the low temperature.”

Solvent extraction methods can effect the protein and nutrient quality and as a result, it’s use in food products for human consumption. This is one of the reasons why it’s commonly used in animal feed, but hasn’t expanded much further.

With the enhanced quality, the possibility of moving into plant-based foods such as plant-based meat, beverage additives, and as a protein additive is much improved.

Vafei added that the process can be customized to a food manufacturer’s needs.

“For example, for some products maybe they need five per cent oil left in the canola meal. So, we can change the pressure, temperature, or the time – if you extract for a shorter time, you can leave the samples with that five per cent. So, you can give a variety of different sample to the food processors.”

Investing in sustainability

However, Vafei admits that the initial investment for this method is expensive. The supercritical extraction system and its equipment is costly to get, as well as investing in proper training of the labour force for operation. But it can balance out over time.

This process eliminates the material use of solvent and can speed up the extraction process, since in many cases it’s more efficient than traditional methods.

“All this change is difficult. And always changing from the traditional methodology to the new technology is difficult. And of course it takes time, and takes some money, but I guess it’s worth it because our planet needs it. Our people need it.”

She hopes that one day this method will be the expected standard, particularly for oil extraction companies. There are changes around the world, so she holds onto the idea.

“I saw some countries, for example Germany, they have started using it (the system) this way. And even in India, I heard they have started using (it), and that means it’s feasible. It’s doable. But I’m not sure about here in North America.”

Vafei’s passion for the environment and sustainability has been a constant, saying it’s something that’s always informed her research. She plans to continue it saying, “it’s our responsibility to care about our planet. It’s the responsibility of individuals and I know lots of things need to be done – it may be very far away – but I am happy to just take one small step in this journey.”